Engineering

Technical issue - idea - concept - drawings - prototype - testing - adjusting - finished product

Luijtech can offer solutions for every product phase.

Machinery

In the past I have contributed in the development of many different products, a few examples are shown beneath.

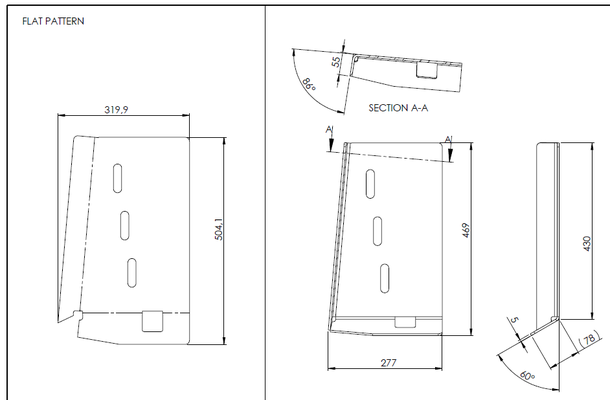

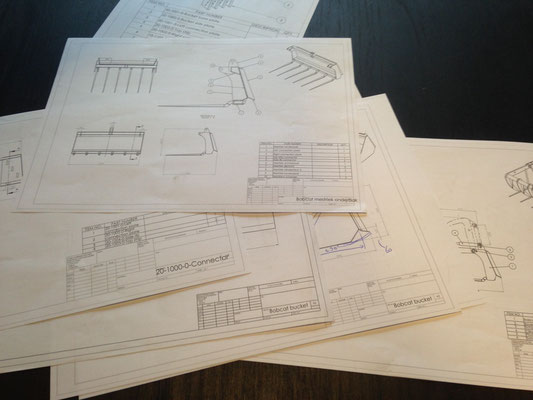

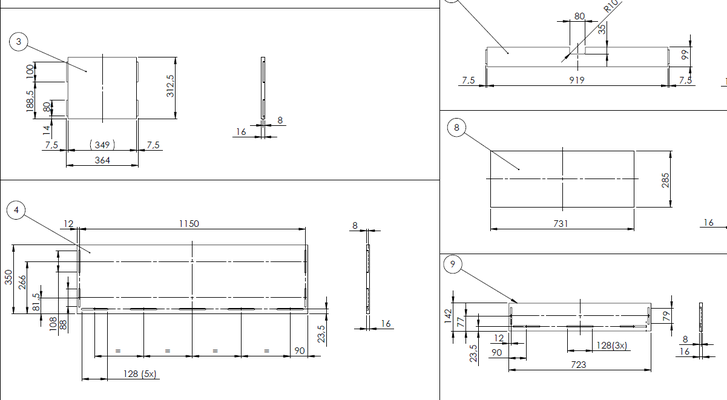

The total process of a simple product

At first the 3d assembly has been made in Solidworks, this consists out of sheetmetal parts. Production drawings are made for bending and quality check. DXF files are generated in order to cut the plates. The finished parts are checked with the 2d drawings. The product is assembled and stitch welded to see if it fits. Finally it has been welded and painted.

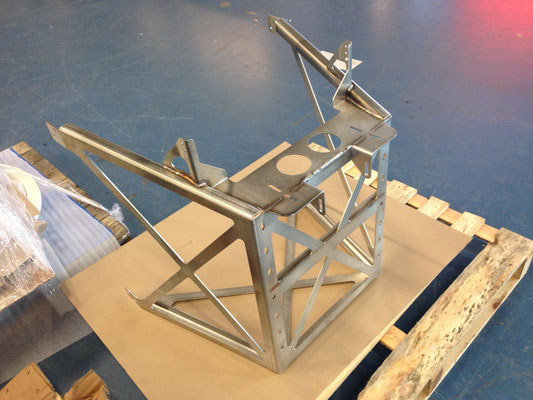

Testing

Setting up a test plan, building prototypes, executing tests, writing testreports. Here under some examples of tests, executed for Haagen Fire Training products.

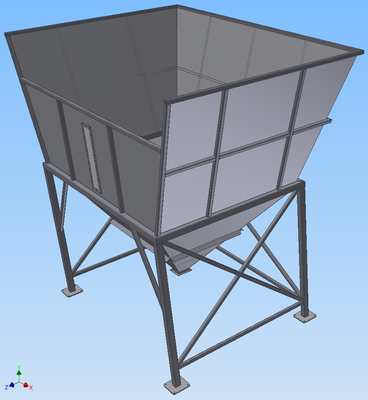

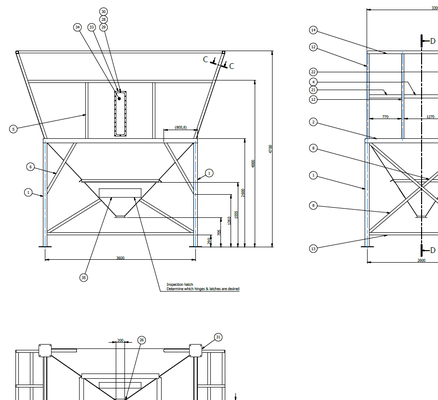

Examples of steel constructions

These products consists mainly out of steel members. The 3d model is leading, if main dimensions are changed, all separate parts will change too. This is helpfull to create an 'interactive' cutlist.

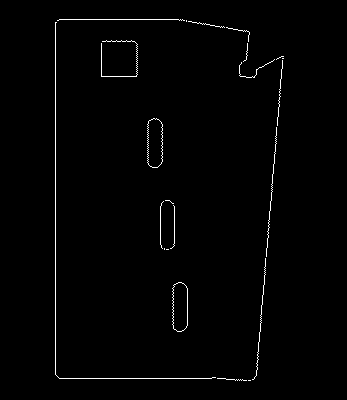

Sheetmetal

The products consists mainly out of steel plates which have been cut & bended.

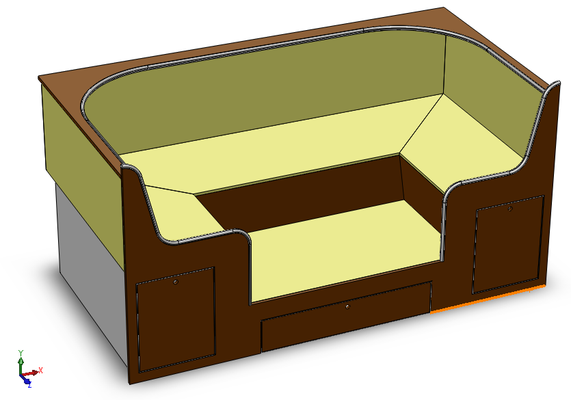

Wooden products

From finished products to 3d drawings, to 2d cutlists. The models have been set up in a way the main dimensions are leading. With a few clicks the entire assembly can be changed and the part production drawings are updated.